-

StrikoMelter PUREFFICIENCY°

- Key Benefits

-

- 489 k Wh/t lowest measured energy consumption

- Up to 99.75 % metal yield

- High metal quality

- 20-year service life

- Key Features

-

- Shaft geometry designed for savings

- Optimized burner alignment

- Long-life furnace lining

- Applications

-

- High Pressure Die-Casting

- High Pressure Die-Casting - Structural Components

- Sand and Gravity Casting

- Technical Details

-

- All the benefits of StrikoMelter shaft furnace technology

- Melting capacity from 1.5 – 3.5 t/hr

- Total holding capacity of between 3 - 10 tons

What happens when your furnace consumes less energy?

Your whole foundry benefits. Which is why we conducted a holistic analysis of our already-efficient StrikoMelter furnace to see if further energy savings were possible.

The result? We reduced consumption by up to 10% to a new low of just 489 kWh/t – making PUREFFICIENCY° the most energy efficient aluminium melting furnace out there.

The modifications made, together with StrikoMelter’s proven shaft geometry, also make a metal yield of almost 100% possible. With energy consumption and metal loss two of the biggest cost drivers that modern foundries face, PUREFFICIENCY° is ready to make big difference to your profitability.

489 k Wh/t lowest measured energy consumption

Unique shaft, unlocked savings

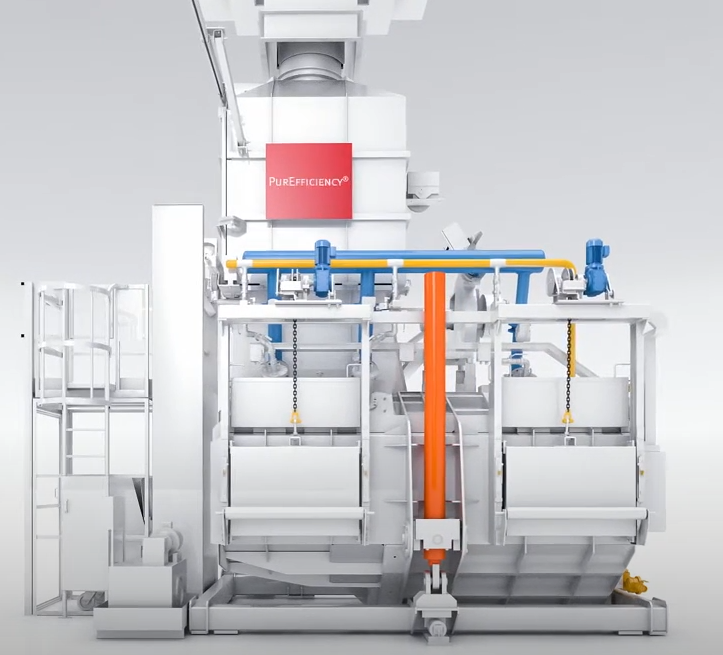

StrikoMelter’s proven shaft design - enlarged for this product line with no additional height requirements - combines preheating, heating and liquefaction in one highly efficient unit.

The counter flow principle employed means exhaust gas from the melted material at the bottom of the shaft is used to gradually heat cold charge material being loaded at the top. This minimizes the time the aluminium needs to spend in the “high temperature” zone, significantly reducing fuel consumption and avoiding metal loss.

Metal quality matters

Reducing metal loss and optimizing quality isn’t simply delivered by clever shaft design. It is factored into every function. For example, the twin chamber construction consisting of a melting bridge and a separate holding bath – with separate, distinct burner systems - limits oxide and dross formation while also minimizing risk of suspended, insoluble contaminants, therefore guaranteeing a high yield of high quality tapped metal.