-

StrikoMelter BigStruc

- Key Benefits

-

- Easily melts huge parts, complex shapes, and/or small returns

- Proven technical performance

- Low metal loss

- Saves time and energy

- Key Features

-

- Modified and enlarged shaft designed for bigger parts

- Laser monitoring for optimized shaft filling

- Shaft cover to prevent heat loss and lower energy consumption

- Charging unit with extra-large charging bins up to 2.9m³

- Near stoichiometric burner settin

- Applications

-

- High pressure die-casting - structural components

- High Pressure die-casting

- Sand and gravity casting

- Technical Details

-

- Melting performance up to 4 t/h

- Holding capacity 6t - 10t

- Shaft enlargement

- Charging unit with extra-large charging bins up to 2.9 m³

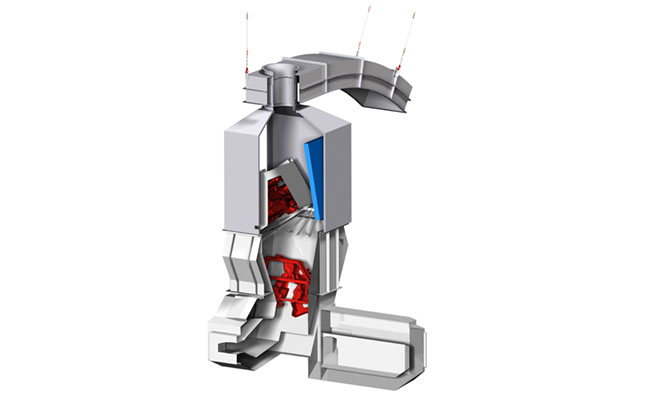

Melting big? Think BigStruc

Need to melt complete stacks of ingots and large-volume, thin-walled parts, just as easily as small-sized returns, all while minimizing metal loss and energy consumption?

Then what you need is StrikoMelter BigStruc – the most versatile system in the StrikoMelter series.

Bigger, done better

Global trends for light-weighting and product design simplification means die casting large aluminium structural components is increasingly common.

Such parts reduce the need for joining and assembly steps and are therefore highly desirable.

They are also challenging to melt. At least with traditional melting furnaces. But not with StrikoMelter BigStruc. Here’s why:

1. Easy to load

BigStruc’s shaft is wider and can easily accept returns of up to 2.5m².

Extra-large charging bins also mean there’s no need to ‘cut to fit’, saving precious time, resource and ultimately - cost.

2. No energy wasted

Bigger parts mean bigger voids and lower bulk density in the shaft, which can result in costly energy wastage.

BigStruc’s hot gas baffle means this won’t happen. The shaft cover ensures heat cannot escape unused, resulting in efficient melting and lower energy consumption.

3. Thin walls, no issue

How do you melt large, thin-walled parts without excess temperature exposure and/or heat variations that could affect quality?

By preheating them in the shaft so that they melt rapidly at the shaft base without direct exposure to strong flames.

The hot metal then flows directly from the melting bridge into the holding bath, where it is heated to the desired temperature.

No fluctuations, no problems.

4. Optimized fill for optimum results

Fill levels are monitored constantly via a laser system (even if the shaft is covered) to ensure the furnace is fed with the right amount of material at exactly the right time to optimize energy use and productivity.

5. Minimal metal loss

Like all StrikoMelters, BigStruc is designed to minimize exposure to oxygen to keep metal loss, low.

For example, self-sealing lift swing doors and near-stoichiometric combustion minimize excess air preventing corundum formation, oxidization losses, and guaranteeing a high-quality yield.